1886 flux used in dental ceramics is.

Dental ceramic firing process.

Mortar seals the spaces between stones keeps water out and helps keep the stones from.

Potters apply a layer of glaze to the bisqueware leave it to dry then load it in the kiln for its final step glaze firing.

Dental porcelain shrinks during firing.

Dental ceramics formed during the firing process are chemically stable inert and resistant to chemical attack.

In dental ceramic sub structures sintered refractory materials have little or no glass.

Ceramic firing support a global icon super peg stabilizes your crown during the firing process leaving you with a post fired benefit you will surely smile about.

They are also biocompatible and have a good soft tissue compatibility.

Dental ceramics for ceramic metal restorations belong to this compositional range and are commonly referred to as dental porcelains.

Troubleshooting and fault analysis.

Ceramic glaze is an impervious layer or coating applied to bisqueware to color decorate or waterproof an item.

For certain dental prostheses such as three unit molars porcelain.

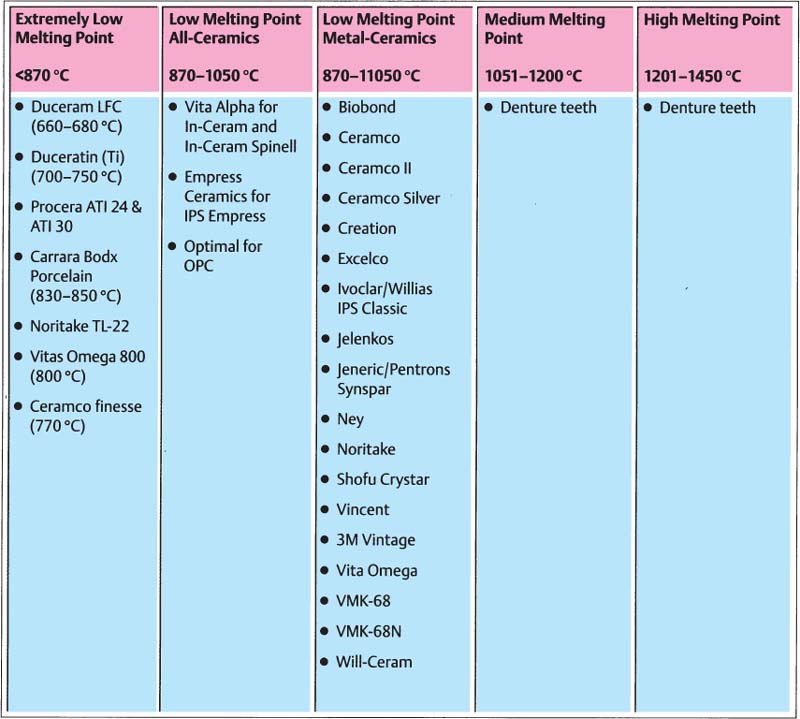

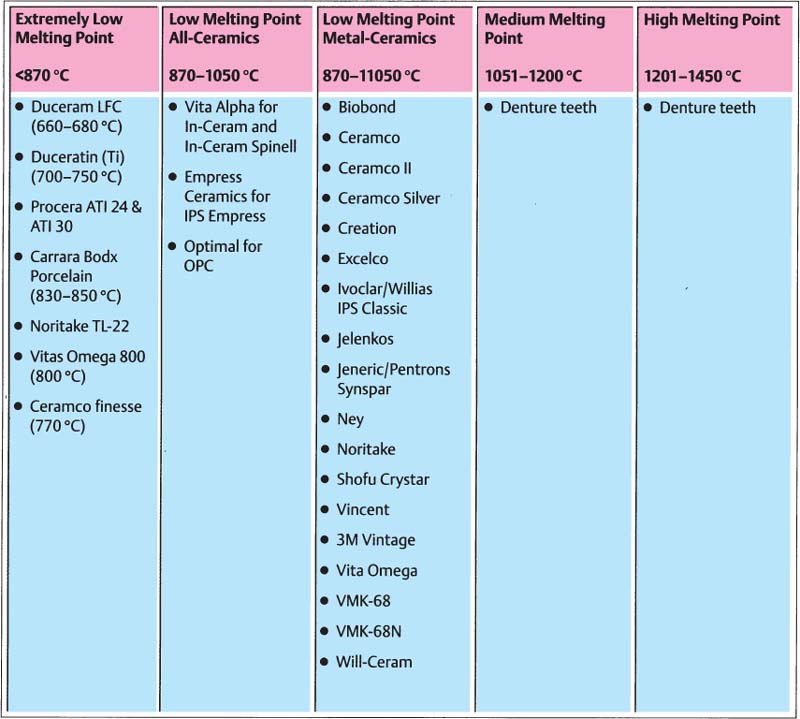

A short firing period at a very low temperature is preferred the melting point of titanium in degree celcius is.

During firing glass in ceramic is similar tothe mortar between stones in a wall.

However strong acids such as hydrofluoric acid can be used to etch the surface of the ceramic.

Dental ceramics are able to mimic natural teeth due to their excellent physical properties such as esthetics biocompatibility low thermal conductibility and wear resistance 1 2 because of these features dental ceramics have been extensively used in several rehabilitation procedures including inlays onlays crowns and porcelain veneers 3 5.

Process control and optimisation.

When porcelain is applied it may have different colors white purple pink depending on the manufacturer.

The process of heating refractory particles until they.

A long firing period at a very high temperature is preferred d.

Dental porcelain also known as dental ceramic is a dental material used by dental technicians to create biocompatible lifelike dental restorations such as crowns bridges and veneers evidence suggests they are an effective material as they are biocompatible aesthetic insoluble and have a hardness of 7 on the mohs scale.

There are many peg putties on the market and all do what they are supposed to do.

First the powder corresponding to the desired shade is mixed with water.

Boric oxide in porcelain metal elements are embedded in the.

Call us to request a free trial and find out what super peg does that the others don t.

The process temperature control rings ptcr by schupp ceramics are ceramic measuring tools that permit measurement of heat inputs up to 1750 c during the firing cycle.