Design for manufacturability support sterilization case tray design capability prototyping machining milling swiss and conventional turning edm laser cutting and welding turret punching press brake forming wire forming silk screening and laser marking electropolish anodize assembly and packaging iso 13485 certified.

Design for manufacturability maximizing the advantages of laser cutting.

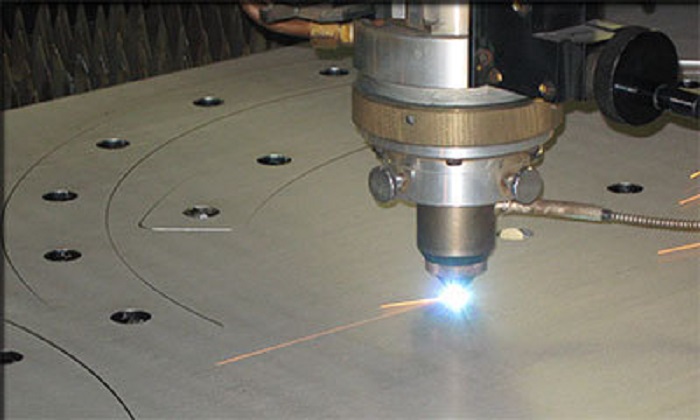

Maximizing the advantages of laser cutting.

Table of contents design for manufacturability.

The first is the possibility of over engineering.

While laser cutting is a useful tool when it comes to design for manufacturing there are a few things that engineers need to consider.

Validating design integrity verifying manufacturability early in the development process can save significant time and costs.

You should be able to import design data into your cam system easily.

In terms of design for manufacturing laser cutting technology can have a beneficial effect on any product.

Each step of a project including design verification detailed quote and production is overseen by experienced engineers.

We excel at providing design for manufacturability assistance to ensure that each part is produced in the most cost efficient manner to all specified tolerances.

We can provide a wealth of design for manufacturability suggestions to speed production improve accuracy and finished part quality.

No matter what process you use milling drilling punching laser waterjet cutting multi access machining or wire edm the critical requirements are starting with accurate 3d geometry and using the machining technology that best fits the needs.

For some manufacturers this may mean moving a laser cut part onto a new piece of equipment increasing part handling quality processes and.

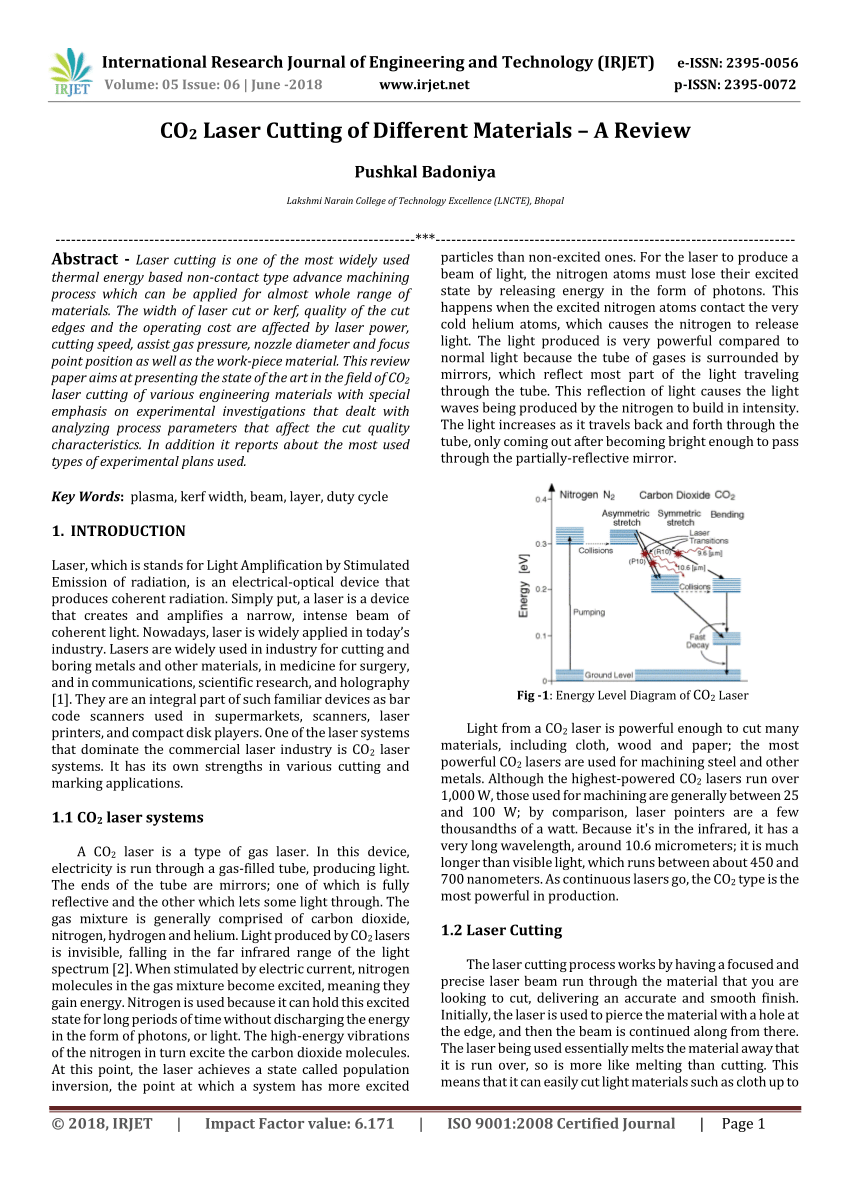

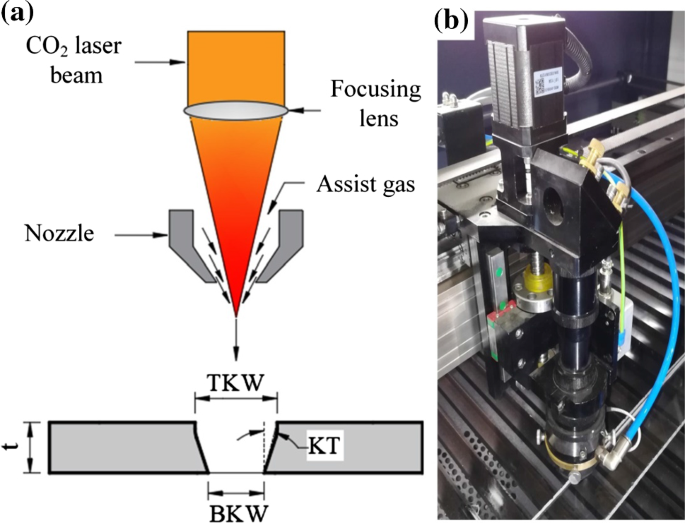

A few practical facts for consideration laser cutting technologies laser technologies.

Maximizing the advantages of laser cutting.

For instance the bend sequence for design c may produce some clearance issues depending on the distance between the bottom back and side flanges the tooling segment widths the operator has available and perhaps the material s overbending requirements to overcome springback.

Cost and quality are two major influences on the marketability of any product and laser cutting allows for high quality components at a lower cost overall therefore making it possible to offer a more affordable better quality product.

All options aid manufacturability and the best choice depends on available machinery and tooling.

While the low cycle times of laser processing provide precision accuracy and high yield production machining processes are sometimes required due to part design or to maximize manufacturability.

Often an engineer who understands the capabilities of a laser cutter will design parts or products with exceptionally tight tolerances.